Lunch Sheet Separator From Food Waste

Undergraduate Project

Principal Supervisors

- Eng.(Mr). Uthayasooriyan Anuraj

- Eng. (Mr). Neethan Rathnakumar

Group Members

- Indushan Senavirathna

- Manuka Ashan

- Senadheera H.D.M.K

- Shafan A.M.M

- Sudharshika R.D.G.F.S

- Somesh Shehan

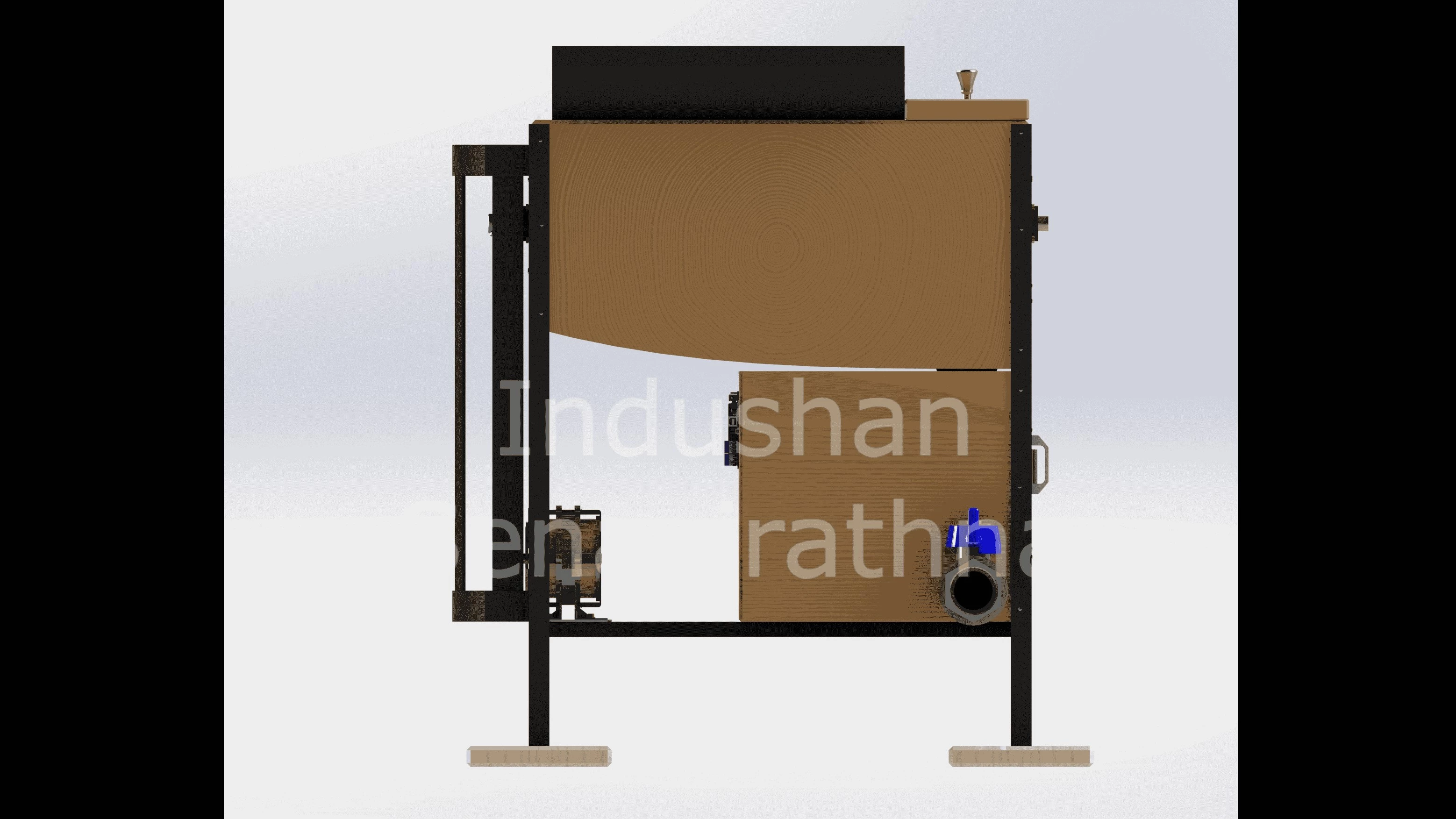

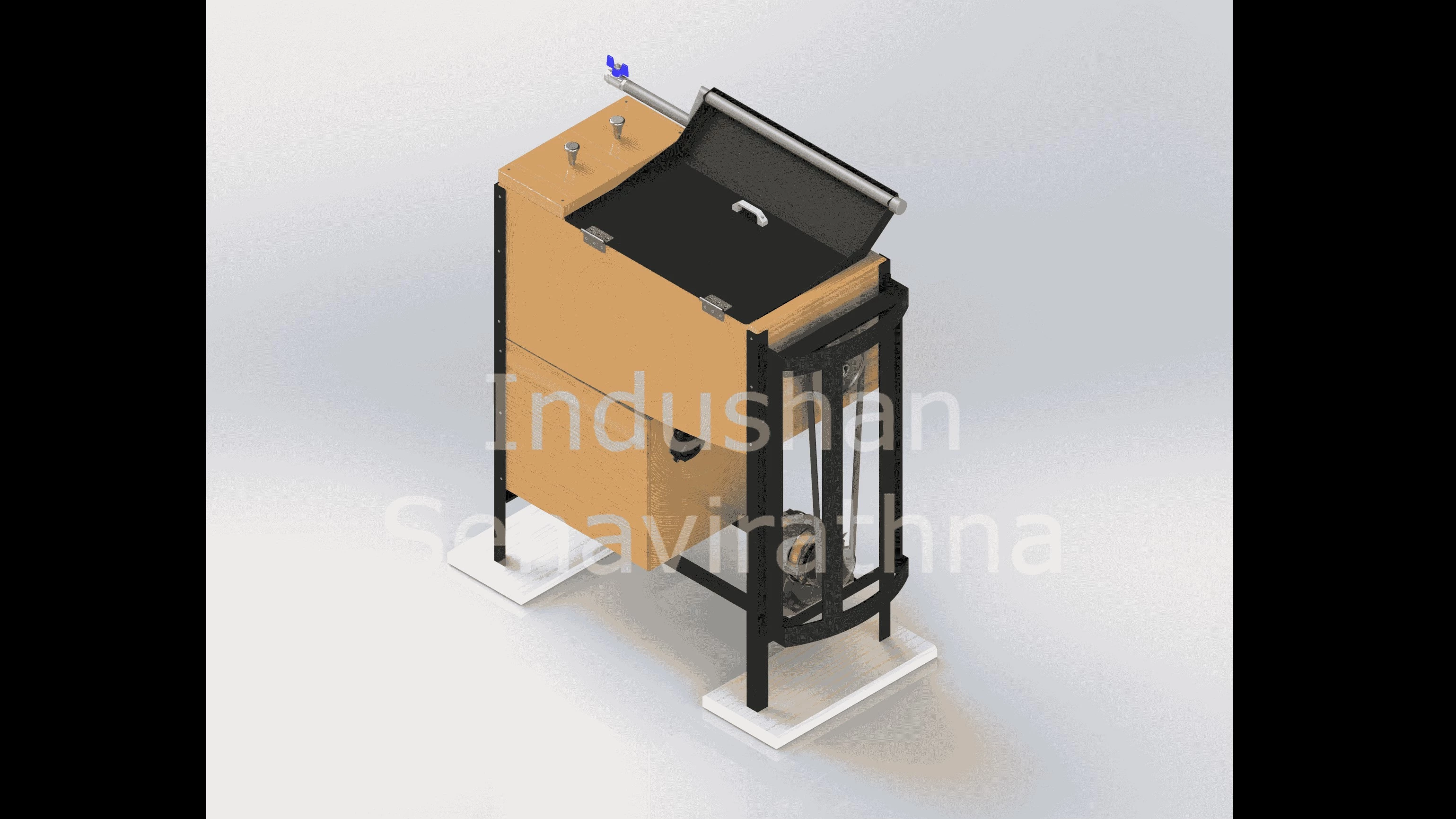

The objective of the present invention is to facilitate the separation and recycling of used lunch sheets from food waste and use the food waste for animal feed. The process involves inputting the used lunch sheets with food waste into the machine, which then employs a mechanical process to separate the washed lunch sheets from the food waste. The separated components are collected in two separate trays, with the food waste being removed independently while the washed lunch sheets are dried using fans and subsequently removed. This machine is designed to be semi-automated, prioritizing user safety, ease of maintenance, and intuitive operation.

At its current stage, the machine can handle a maximum weight of 2 kg of lunch sheets with food waste per cycle. However, there are plans to further develop the prototype for mass usage and aim for full automation. The ultimate goal is to recycle the used lunch sheets effectively and efficiently. During the machining process, the lunch sheets are separated from the waste food particles, followed by a thorough washing to eliminate any remaining food particles. Finally, the lunch sheets are appropriately dried. The entire system is designed to optimize safety, maintenance, and user experience.

It is worth mentioning that this machine holds potential for mass application and has been designed with scalability in mind. By successfully separating and recycling used lunch sheets, it contributes to waste reduction and promotes environmental sustainability.

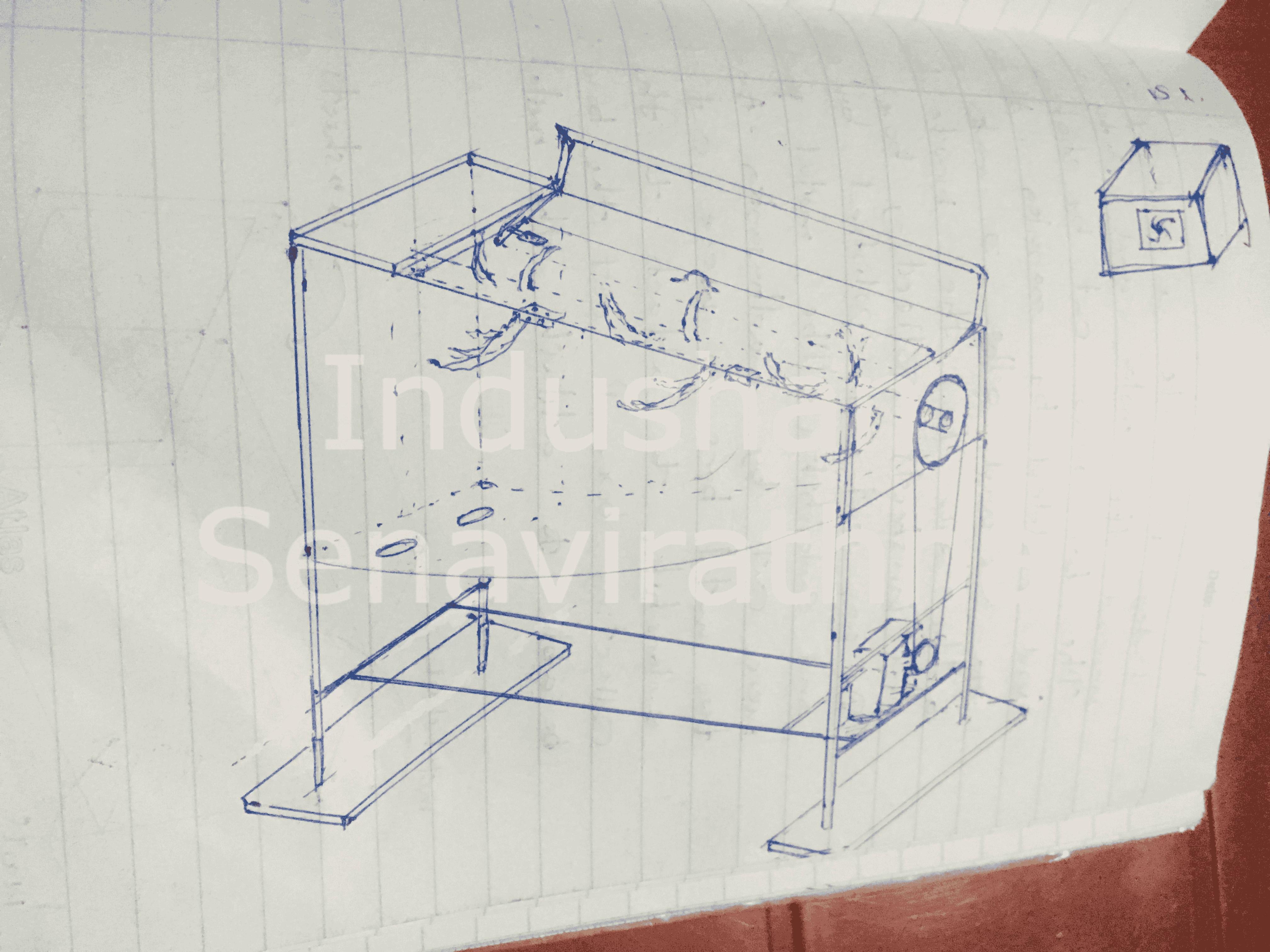

Our project incorporates a special hooking mechanism specifically designed for separating polythene and food waste. This mechanism plays a vital role in the overall operation of our system.

Currently, our system is semi-automatic and relies on the use of water for the separation process. We utilize water to effectively separate the polythene from the food waste. This water-based separation technique ensures the efficient removal of food waste particles from the polythene.

The design and implementation of our hooking mechanism, along with the water-based separation process, are tailored to meet the specific requirements of our project. The combination of the hooking mechanism and water separation method showcases an innovative approach to address the challenge of separating polythene and food waste.

It's important to note that we continue to explore opportunities for further development and optimization of our system. Our aim is to increase automation and potentially investigate alternative methods for separation that could reduce water usage or enhance overall efficiency

- Development of a semi-automated machine for separating and recycling used lunch sheets from food waste.

- Implementation of a mechanical process for efficient separation of washed lunch sheets from food waste.

- Collection of separated components (food waste and washed lunch sheets) in separate trays.

- Drying of washed lunch sheets using fans for subsequent removal.

- Focus on user safety, ease of maintenance, and intuitive operation in the machine design.

- Potential for mass application and scalability of the machine.

- Contribution to waste reduction and environmental sustainability through effective recycling of used lunch sheets.

- Incorporation of a specialized hooking mechanism for separating polythene and food waste.

- Utilization of a water-based separation technique to remove food waste particles from polythene.

- Ongoing exploration of opportunities for further development, automation, and optimization of the system, including alternative separation methods and reduced water usage.

Skills

- Embedded Systems

- C Programming

- Motor Selection

- Torque Calculation

- Solidworks

- Mechanical Workshop Tools and Equipment Handling

- Material Selection

- Fluid Dynamics

- Automation

- Manufacturing and Assembly

- Safety and Compliance

- Optimization and Efficiency

- Team management

- Mechanical Design

- Prototyping and Development

- System Integration

- Problem Solving

- Scalability and Mass Application

- Environmental Awareness